-

Enquiry Form

-

Enquiry Form

-

Enquiry Form

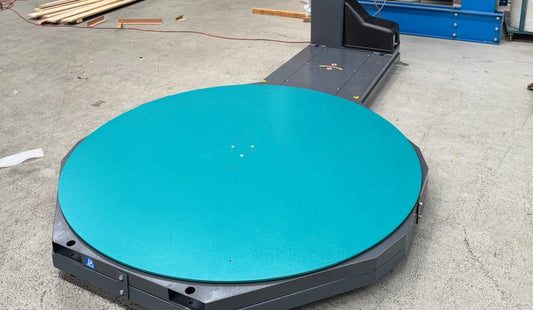

Atlanta Stretch

MPS Packaging Import and distribute Italian made pallet wrappers from Atlanta Stretch, Atlanta stretch is a global manufacture and brand known for the quality and robust machines.

MPS buy direct and sell direct, offering end users an unbeatable price for a high quality Italian made pallet wrappers.