-

Sold out

Sold out -

Enquiry Form

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Enquiry Form

-

Enquiry Form

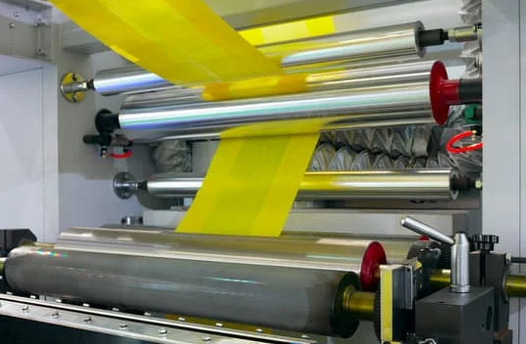

Custom made plastics

MPS have been providing custom made plastics throughout Australia since 1977, we can provide a full range of locally produced and imported. Timberwrap, shrinkwrap, poly bags, seal bags, courier bags, padded bags, in a massive range of colours, additives and printing options.

Custom made plastics

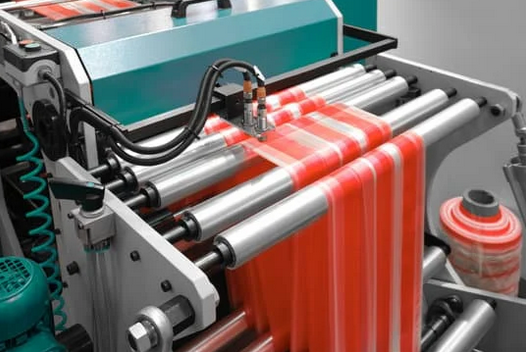

Custom Printed Plastics

LDPE, MDPE & HDPE

MATERIAL TYPE

MPS can produce plastics in a wide selection of material types. While LDPE is the most flexible HDPE is stronger and denser and great for barrier items such as liner bags, MDPE is a mix between the 2 where strength and flexibility is important.

Choose your own colour.

Colour Selection

While most of our plastic is produced in clear, black or white, we can produce plastics in a various range of colours, this can be useful for branding & identification.

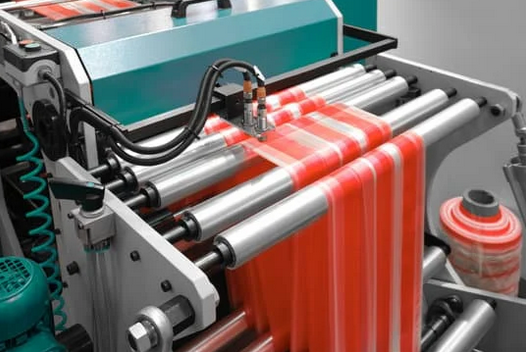

Add your information and brand

Custom plastic Printing

Many of of plastics can be customized with your logo, design branding and artwork. This can make your product standout can be easily identifiable. Printing can be done as multiple colors and print sides.

Additives for special applications

Additives

When producing plastics, ewe can add various additives to the product for special uses. Some common additives include, UV stabilizer for increased longevity in the sun, VCI additive, for its anti corrosive properties, anti block material to allow for easier opening of bags, EVA to increase strength in frozen applications. High slip or low slip additives to increase or decrease friction of the product.

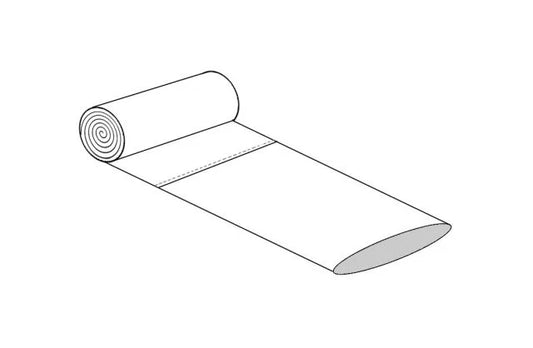

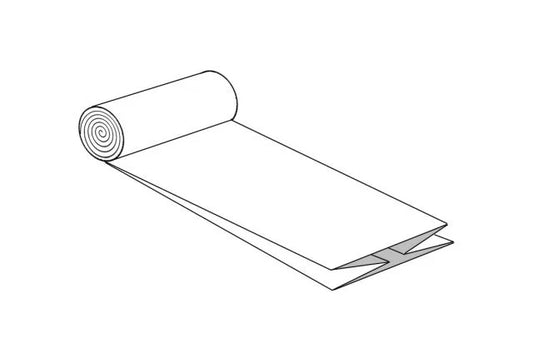

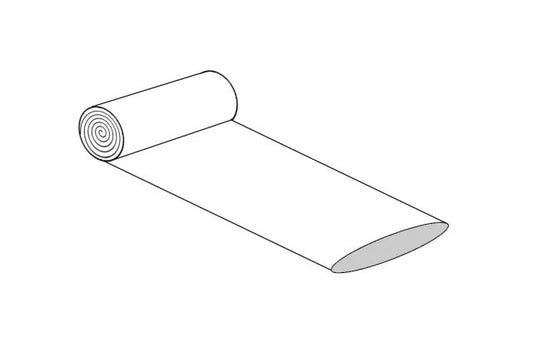

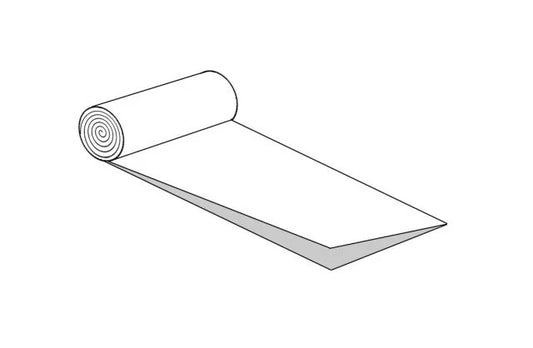

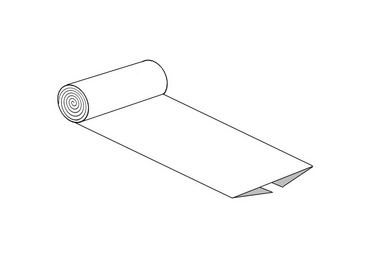

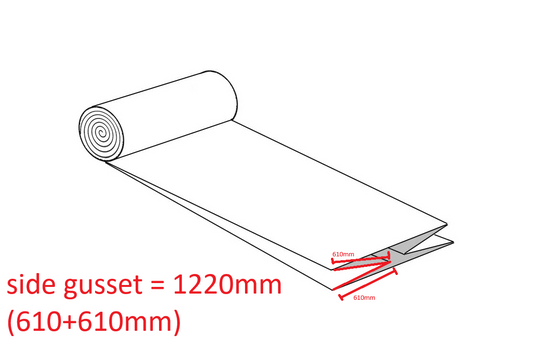

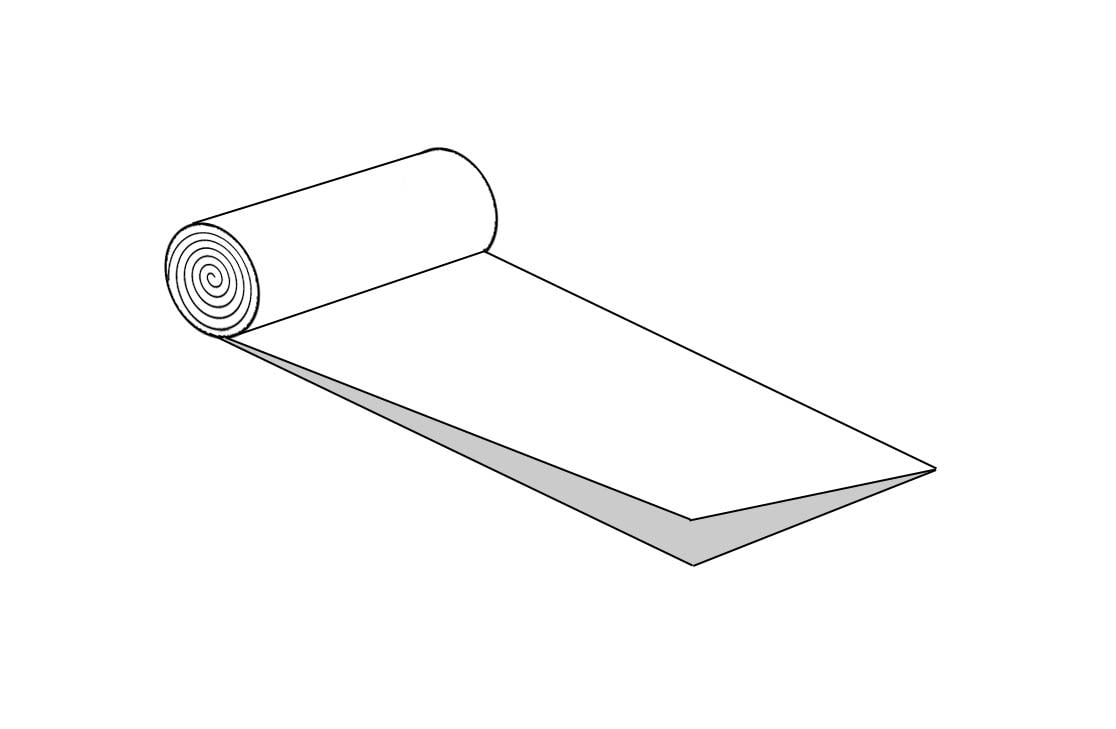

TUBE, SHEETING, U FOLD, BAG ON ROLL, SIDE SEAL BAG.

Winding and bag types

MPS can produce a massive range of custom made plastics in various styles. be it the standard Tubing, Centerfold sheeting, bag on rolls, Loose bags, courier bags, die cut bags, shrink wrap, single wound sheeting