CUSTOM PRINTED TAPE AND LABELS

CUSTOM PRINTED TAPE AND LABELS

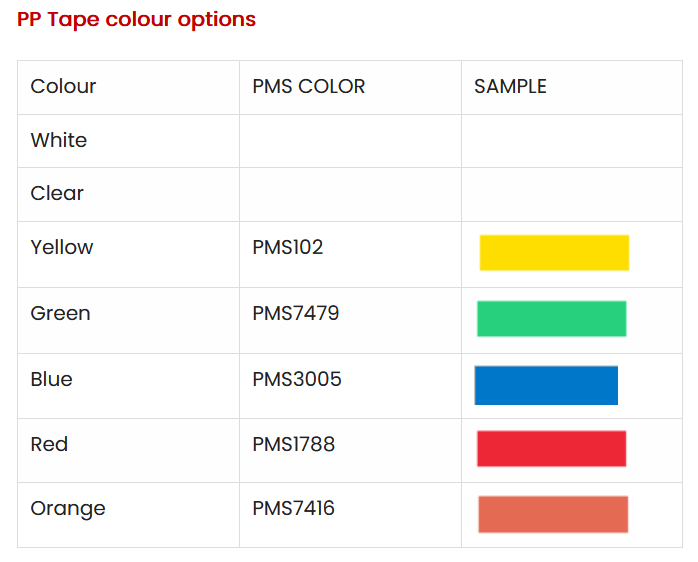

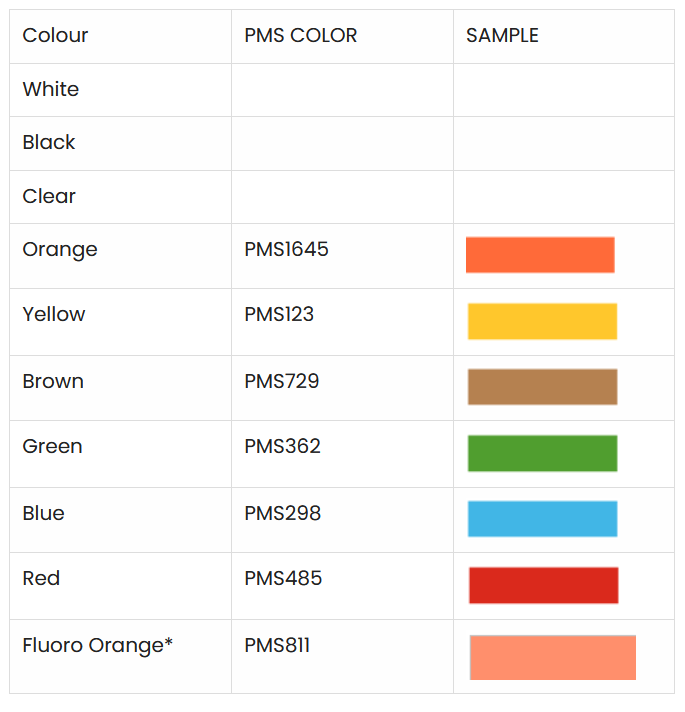

Custom printed tape and labels are an effective way to promote your brand while clearly identifying your goods. We offer tape printing in up to five colours (in addition to the tape colour) and in two different material types.

If you only need custom wording rather than a logo, you may be able to save on setup costs by using one of our existing print blocks. We already have plates for common messages such as FIS, WARNING, HEAVY, DO NOT BEND, TOP LOAD ONLY, and many more. From there, you can select the tape style and colour that best suits your needs.

Out of stock

MPS Printed tape

MPS have been providing printed to clients around Australia for close to 50 years. We have a long experience in provide printed tape and labels to a rnage of clients. With this we also have a range of generic printed tapes which may suit your printing purposes.

Printed tape materials

We supply printed tape in a range of material types.

The solution for boxes

Custom printed PVC tape

The PVC tape is a premium tape, it can be used on a wide range of

surfaced and sticks well to cardboard and recycled cardboard. RIP A labels will use the PVC material but they will be limited in a clear coat which makes the colours look more rich and glossy.

The cost effective solution

Custom printed PP tape

PP tape is general purpose tape, its good for going onto plastic or adding a logo to a carton that already sealed. We don’t recommend the PP for long-term applications on cardboard.

Printed tape artwork

Please note that the pantone colours wont look the same in real life as they do on a computer screen. See here for a comparison vs proof.

The colours when printed look more vibrant.

Some previous jobs

These are some of our printed tape, while many of our clients tape look great we don't disclose any customers printed jobs online

Ordering Process for printed tape

Printed tape ordering process

Order Processing steps:

Step 1: Initial contact & consultation

Give us a call our use our contact from to get in contact with us, we will go over the size of tape required and how many colours you would need, if you can send us the artwork you’re looking to have printed at this stage it would be great, so we can look address any potential issues we may have in printing your required artwork. We don’t need to see the artwork to quote if you haven’t finalised what you require. However, the quote isn’t fully valid until we see the final artwork.

Step 2: Submission of quote

MPS will send you a quotation for the printed tape / label job for you to review pricing.

Step 3: Accepting the quote / sending purchase order.

If you would like to go ahead with the quote, send us a purchase order or written confirmation to go ahead. You should also send the artwork required at this time. We will review the artwork for any issues and resubmit the quote if required.

Step 4: Payment

If you’re a new account or cash sale, we will require payment before proceeding further.

Step 5: Artwork approval

Before printing the job we will send an official artwork proof for your review and approval, you can make changes here and check for any spelling or grammar mistakes or may changes to the layout. Please check the artwork thoroughly as we cannot accept returns on custom printed products.After the artwork is approved typically there is a 1-2-week lead time until you receive the goods.

Step 6: Delivery

Once the printing of the tape or label is complete, we will arrange for it to be delivered to you, or you can pick it up from our warehouse in Kilsyth if that is your preference.

Contact form

Other Custom made products

-

Sold outRegular price $0.00Sale price $0.00 Regular priceUnit price perSold out

Sold outRegular price $0.00Sale price $0.00 Regular priceUnit price perSold out -

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per

-

Regular price $0.00Sale price $0.00 Regular priceUnit price per