A side gusset in plastic packaging refers to an extra fold that is added to the sides of a bag or tube. Instead of the plastic being completely flat, the material is folded inward along each side, creating extra depth when the bag is opened or filled. Its commonly used in custom made plastics or some of our stock plastics.

This design allows the bag or tube to expand more easily and hold bulkier or irregularly shaped items—things that wouldn’t fit neatly into a standard flat bag. For example, a side-gusseted bag will sit more square or rectangular when filled, rather than stretching or looking messy at the bottom.

Side gussets are commonly used for:

-

Large industrial bags or tubing, where making one huge flat tube is impractical or impossible.

-

Packaging square or round products, like boxes, rolls, or bulky items.

-

Transport efficiency, since narrower gusseted rolls are easier to handle and ship compared to very wide flat rolls.

When specifying a side-gusseted product, the gusset size is usually listed along with the width (e.g. 1220mm x 1220SGmm), which defines the full circumference once the gusset is expanded. So for example the 1220 x 1220SGmm bag when opened up would have a total circumference of 4880mm.

As we use the formula: (Width + side gusset) X 2.

(1220 x 1220) x 2. = 4880

How is a side gusset measured?

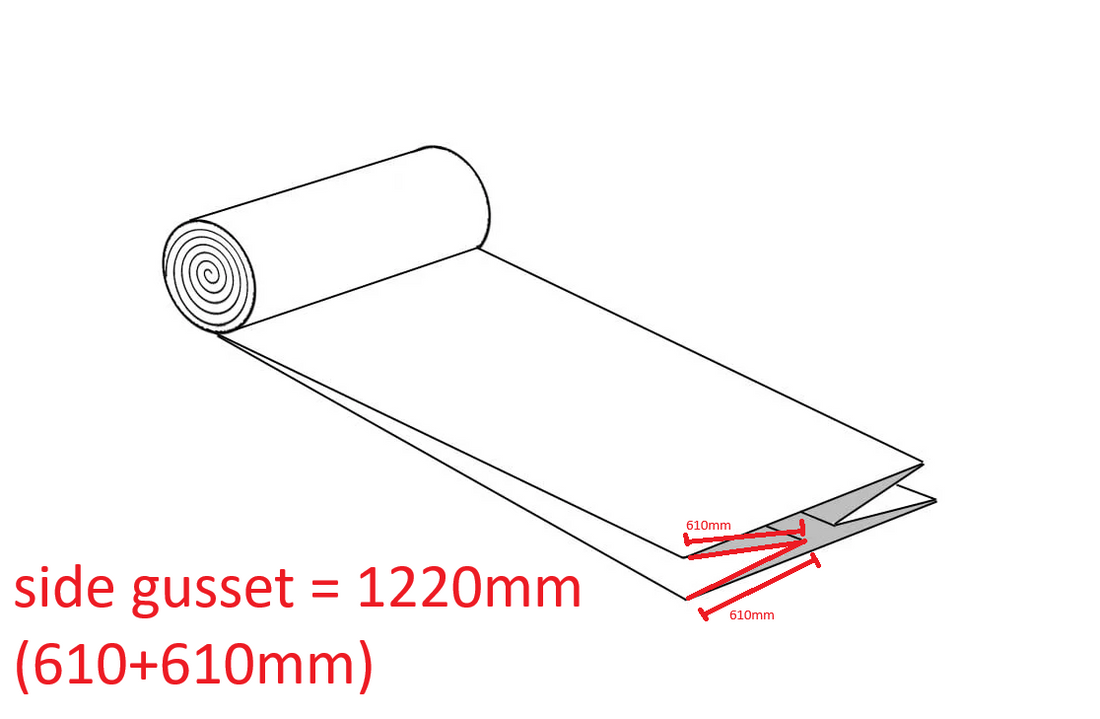

A side gusset is measure by taking thew total length of the side gusset. in the image below we can see the side gusset highlighted and then the length of the parts of the side gusset measured. in the reference image below. the SIDE GUSSET WOULD BE 1220MM

Some manufacturers may list this as 610+610. But it should NEVER be expected that if a side gusset is listed as 610mm it would give 1220mm length.

Side Gusset for packaging and transport purposes

One of the main reasons a side gusset is used, is for packaging and transporting. Using the measurements above for example, if we wanted a 4880mm plastic sheeting, we could potentially wind it to be a single wound sheet that is on a roll which is 4880mm wide. However that is entirely impractical to transport. Instead using a side gusset we can bring the roll width down to 1220mm which is entirely more manageable from a production and transport standpoint.

Side gusset for packaging rolls or square items.

Lets now look at packaging an items.

lets for example say we want to package an item that is:

1000mm x 1000mm, width times depth, its height is irreverent in this as we can make the bag length whatever we want.

This product then has a circumference of 4 meters.

Lets for example saw we then made a bag that is 2050mm wide, giving us a circumference of 4100mm, so an extra 100mm to make sure we can get the product in there.

What will happen is at the base of the bag, the ends will come out in a point and flare out. This will give a look which is not neat and look unprofessional, while this style bag will suit more shallow rectangular goods, its not as nice for doing products which are round or square.

By using a side gusset the ends of the bags are folded inwards, creating a more tight fit around the product and a much neater look.

You can see below how this pallet bag uses a side gusset. the bag folds neatly at the top because of the side gusset and fits the square item perfectly.

We hope you found this information helpful, please do contact MPS Packaging if you are looking for custom made LDPE side gusseted, bags, shrinkwrap or poly tubing to be made for you.