Neos – Pallet Wrapping Robot XF-N3

Neos – Pallet Wrapping Robot XF-N3

The Neos pallet wrapping robot is a high end robot built by Atlanta stretch in Italy, featuring, HMI Panel, Powered prestretch head unit, safety stop bumper and operation light tower the Neos is a cut ahead of the competition.

No need for an oversized machine or turntable, it can wrap anything or square or rectangular shape.

AYRA SYSTEM NOT INCLUDED IN THIS VERSION. PLEASE NOTE THE AYRA BLOW TO ATTACH AND CUT SYSTEM IS NOT INCLUDED IN THIS MODEL VERSION.

3 in stock

Enquiry Form

Atlanta Stretch Pallet wrappers

MPS sell pallet wrappers from international brand and Italian manufacturer ATLANTA STRETCH. ATLANTA STRETCH pallet wrappers are used throughout the world and known for their robustness, low maintenance and low cost of ownership.

MPS buy direct and sell direct, offering end users an unbeatable price for a high quality Italian made pallet wrappers.

Blog posts

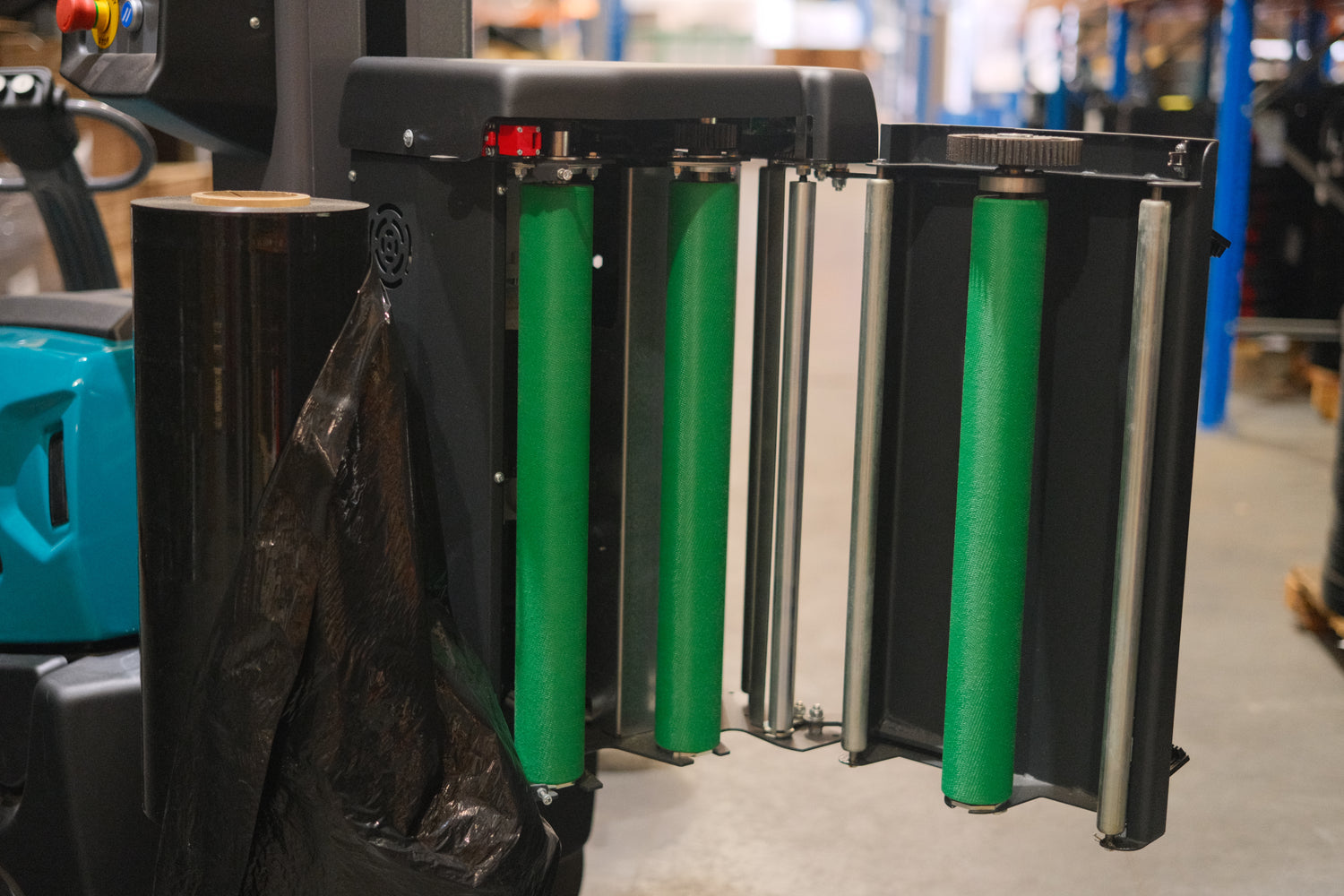

Use of industrial Components

Industrial design & Components

Atlanta stretch build machines with ease of replacement parts in mind. where possible they use commercially available industrial components.

component

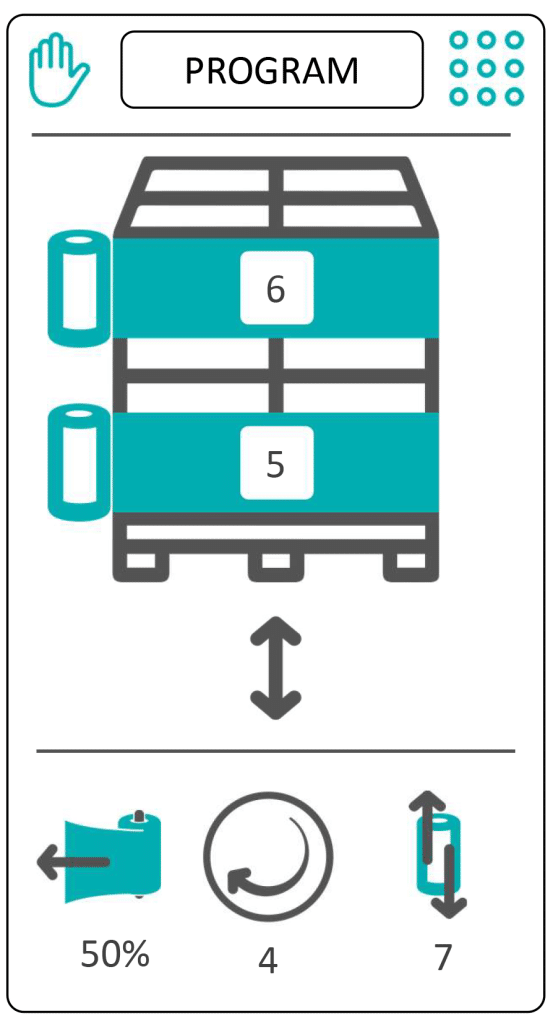

HMI Screen

The Neos HMI screen is easy, simple and fast to use. the pictograms are intuitive to use and the range of parameters and adjustable

options are more than enough to get your pallets wrapped to your desired

wrapping settings.

Guide wheel

Robotic guide wheel

The heavy duty robotic guide wheel guides the pallet wrapping robot around the pallet simply and easily.

safe for all

Fully enclosed mast design

Atlanta stretch build machines and robots with a fully enclosed mast design, this means that all components for the carriage to operate are inside the mast, the upper and lower limit switches, the chain, cable loom, microswitches and the main bearings of the flange are all internal.

This internal design design means there is less chance of components failing due to dust or moisture, they cant be knocked and people cant get their fingers in there.

Generic components for high ware buttons

Industrial buttons

The Neos makes use of industrial buttons for the high use start, stop, enabling, and emergency stop. these buttons are quick and easy to replace if they ware out or break and easily obtainable from your local electronics supplier.

Atlanta stretch dont try to lock you into using their parts and buttons. Their goal is to build a robust machine with low service requirments in mind.

Advanced features

Light tower

The Neos light tower warns users from a distance of its operational status and any errors, the modern and sleek design not only looks great but standard out easily from a great distance.

Robotic power

Movement buttons

The Neos features forward and reverse buttons built into the handle to move the robot from each pallet. This design greatly reduces operator fatigue when moving the robot.