-

Enquiry Form

-

Enquiry Form

Orbital wrapping machines

How Orbital Wrapping Machines Work

MPS Orbital wrappers

Our company was established in 1977 in Melbourne, Australia. We are a 100% Australian owned an private company.

In this time we have Distributed thousands of wrapping machines nationwide to clients seeking high quality wrapping machines at an affordable price.

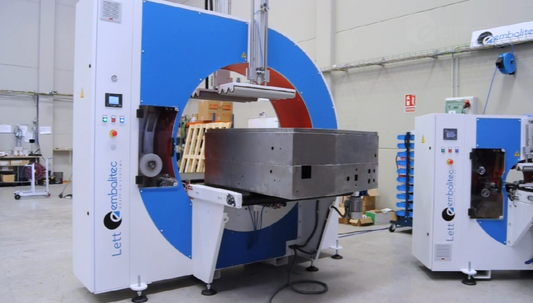

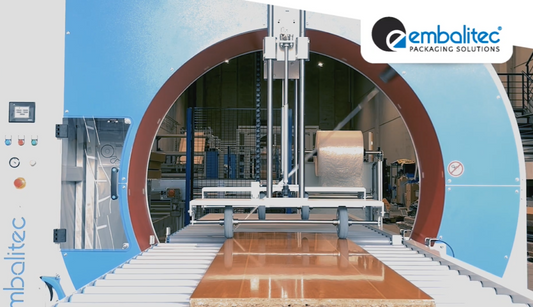

EMBALITEC PACKAGING SOLUTIONS

Embalitec is a leading innovator in industrial packaging solutions, specialising in orbital and stretch film wrapping machines for a wide range of industries. Known for their precision engineering, reliability, and efficiency,

Embalitec machines are designed and manufactured in Spain to handle

everything from long and heavy profiles to delicate products requiring

careful protection.

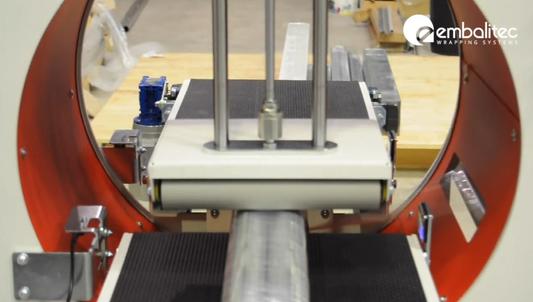

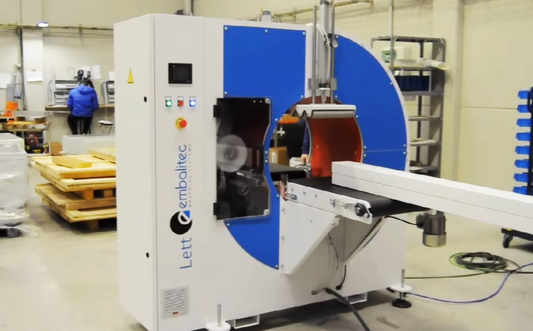

Efficient horizontal wrapping

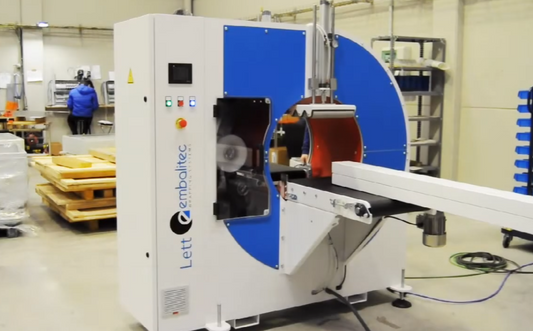

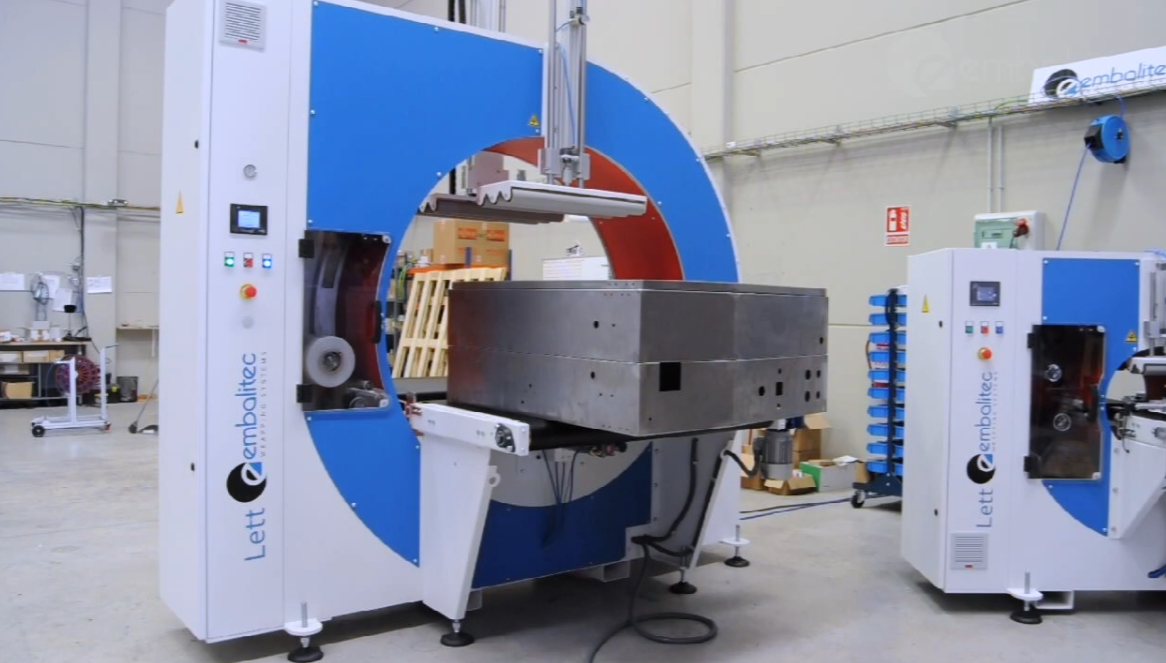

The LETT Series

The Lett Series is the most popular Embalitec machine, this highly efficient wrapping platform is available in 400mm, 600mm, 100mm, 120mm and 150mm wide rings.

The Lett series is available in semi automatic and automatic modes.

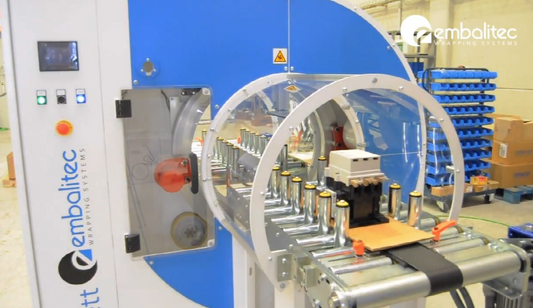

High speed machine for profiles

Profil wrapping machine

The automatic wrapper for profiles and mouldings is a specialised machine designed to streamline industrial packaging. Using a rotating crown, it applies stretch film horizontally around each product, providing even coverage and reliable protection. This fully automated system enhances packaging efficiency by ensuring a consistent film application, securing profiles and mouldings for safe transport and easy handling throughout the supply chain.

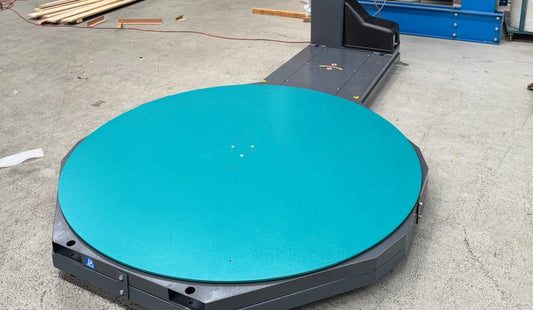

The most economical packaging system

Krone orbital wrapper

MPS Packaging is home of the Manual pallet wrapper wrapper in Australia, The Marathon wrapper is a uniquely portable, non-electric solution. Ideal for wrapping normal, large or oversized pallets. The Marathon is capable of uniformly wrapping pallets due to its use of prestretched pallet wrap. The marathon eliminates the need to bend over when wrapping and for the need to overextend your arms when trying to wrap high.

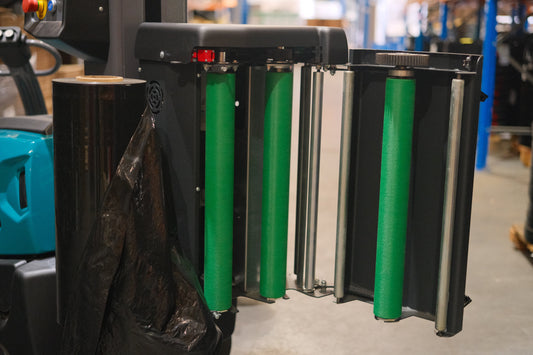

Custom your Embalitec machine

Custom orbital wrappers

When it comes to Orbital wrapping goods, not every product is quite the same, this is where Embalitec comes in, custom upgrades and add on can be produced to insure the upmost efficiency in your packaging line./

Lett orbital wrapper overview

Orbital wrapping machine blogs

Pallet wrapper Contact form

Dedicated teams for aftersales support.

Pallet wrapper guides and training

MPS is with you every step of the way when it comes to aftersales support. Whether on-site, over the phone, or online, we’re here to help. We’ve created a comprehensive library of pallet wrapper guides, all freely available online for your convenience. Need additional information, phone support, or video training for a machine you’ve purchased? No problem—MPS is fully committed to providing reliable, accessible aftersales support for all our pallet wrappers.

Massive range of options

Custom pallet wrapping machines

MPS Can supply a range of custom options for pallets wrappers, be it a simple ramp, scales, oversized frame custom panel, attachments such as roping, strip cutting, top press or options such as zinc coating or Stainless. We're also able to supply cold weather pallet wrappers for freezers.

Orbital wrapping film

MPS Supply a range of orbital wrapping film for our machines and any other orbital wrappers, we have capacity to supply stock film in 125mm x and 250mm wide film on 3 inch core. We also have custom slitting facilities for stretch film. so we can make Orbital or spiral wrapping films in other sizes such as 38mm core.