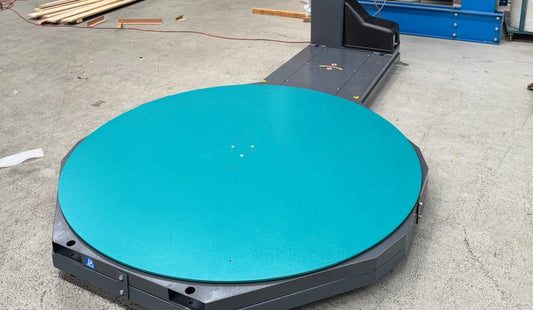

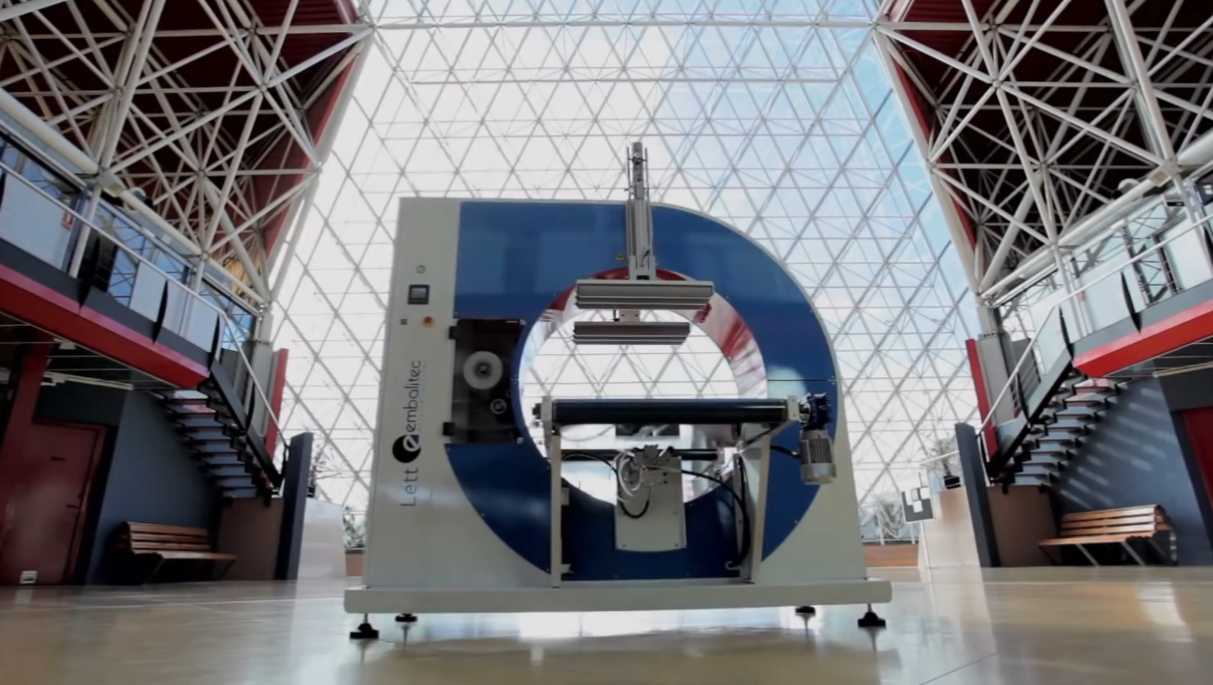

Orbital wrapping machine Lett-60

Orbital wrapping machine Lett-60

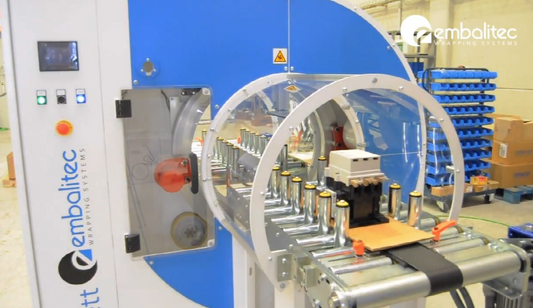

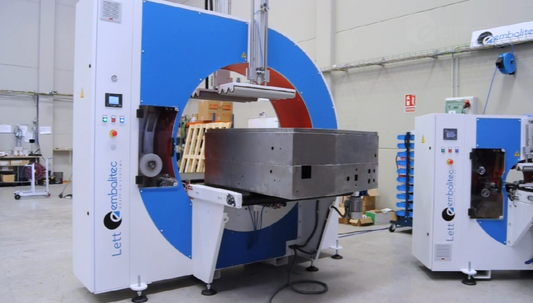

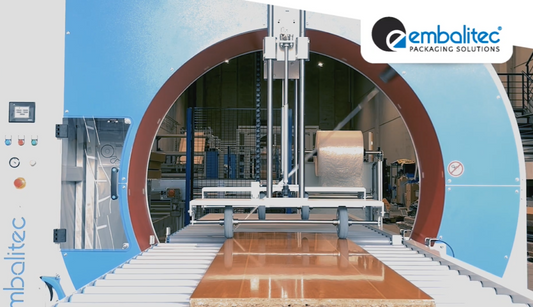

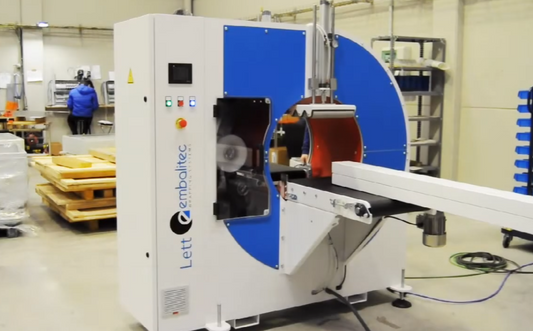

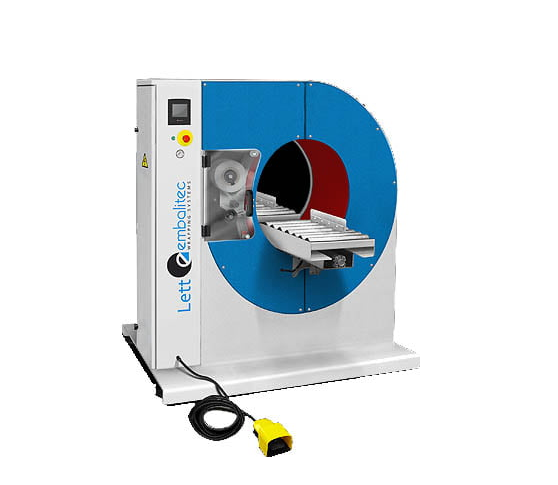

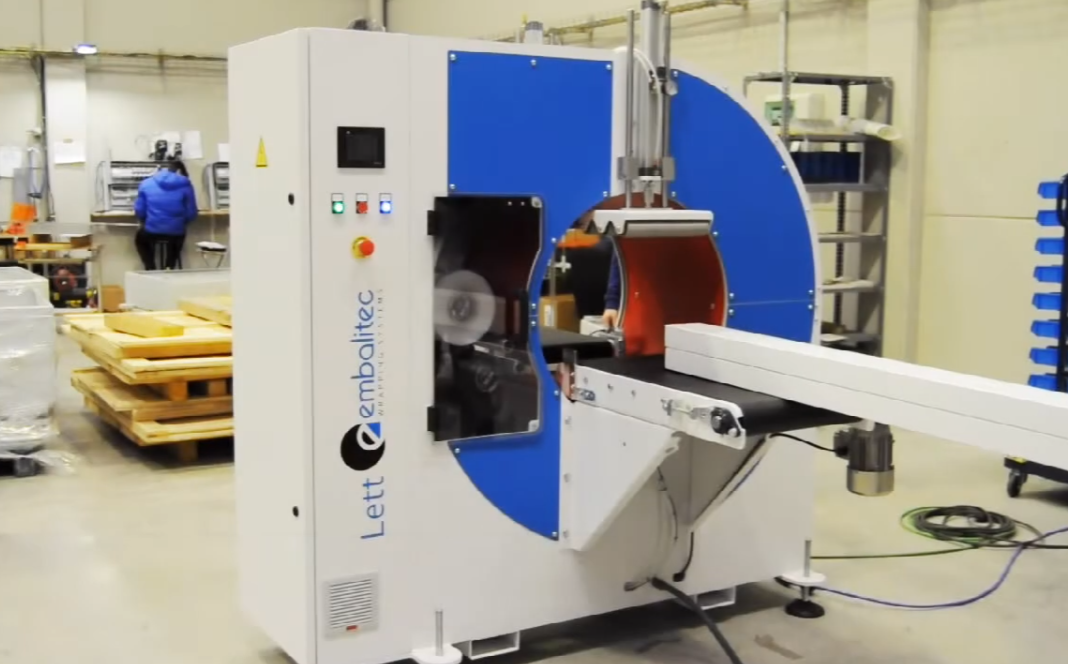

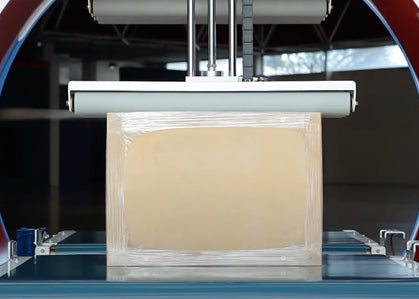

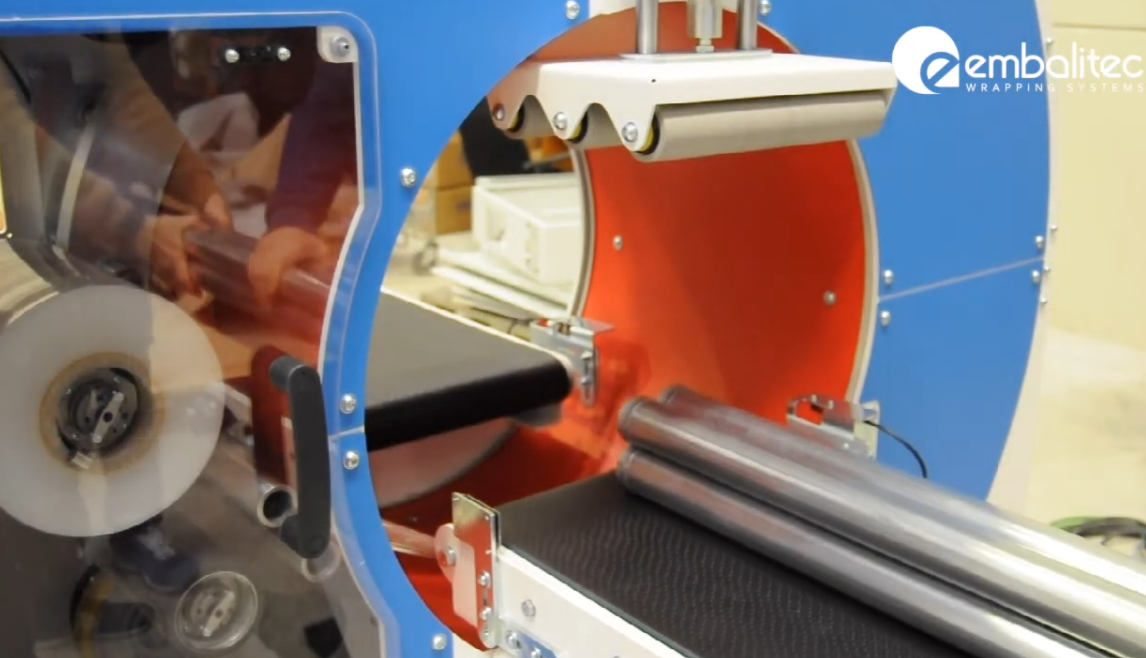

The Lett 60 is an orbital Stretch film wrapping machine with rotating ring for continuous or banded wrapping

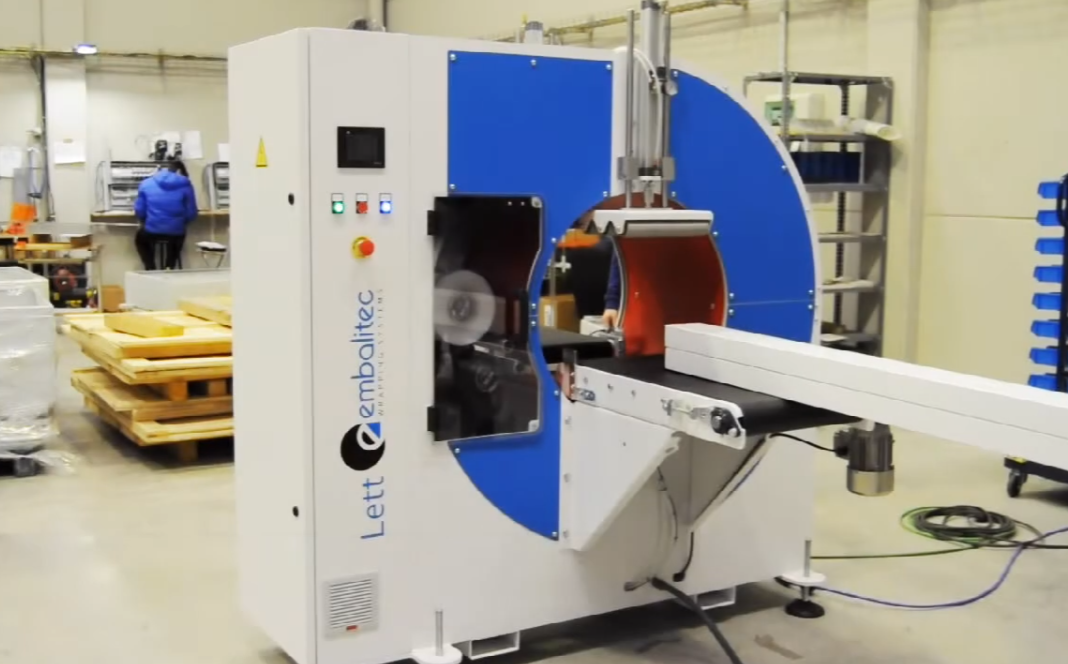

This advanced wrapping system delivers a highly efficient solution for securing and protecting products. The Lett-60 it applies stretch film evenly around each load, ensuring superior stability and protection. Ideal for both continuous production lines and setups using standalone conveyors or motorised rollers, it adapts seamlessly to a variety of packaging operations.

The Lett-60 Is available in Semi automatic and Automatic models

Enquiry Form

Embalitec Orbital wrappers

Embalitec is a leading innovator in industrial packaging solutions, specialising in orbital and stretch film wrapping machines for a wide range of industries. Known for their precision engineering, reliability, and efficiency, Embalitec machines are designed and manufuauctered in Spain to handle everything from long and heavy profiles to delicate products requiring careful protection.

Lett Series Orbital wrapping videos

How the Lett Series Operates

STEP 1

Feeding and Detection

Products are transported along conveyor belts or motorised rollers to the wrapping station. As each item arrives, a sensor detects its presence and automatically synchronises the rotation of the wrapping ring with the movement of the line, ensuring a smooth, continuous, and precise application of stretch film.

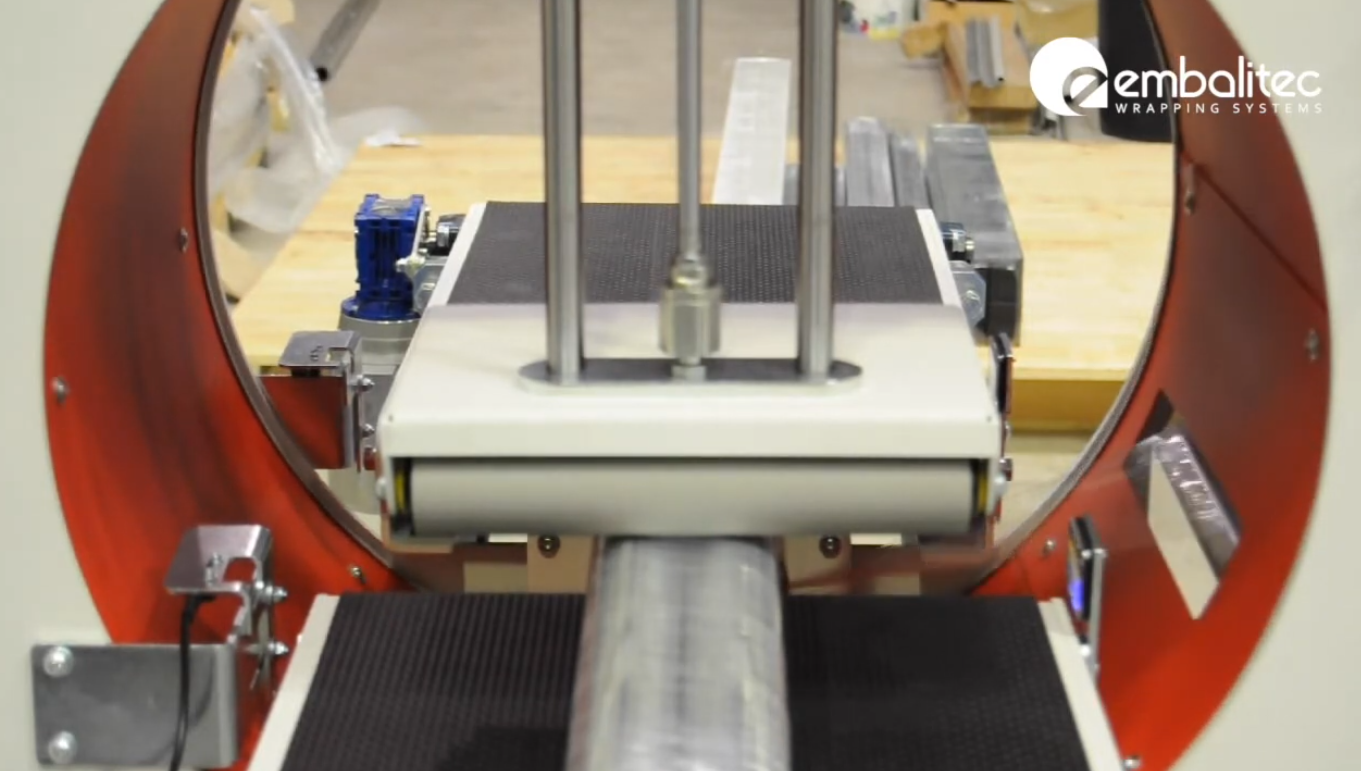

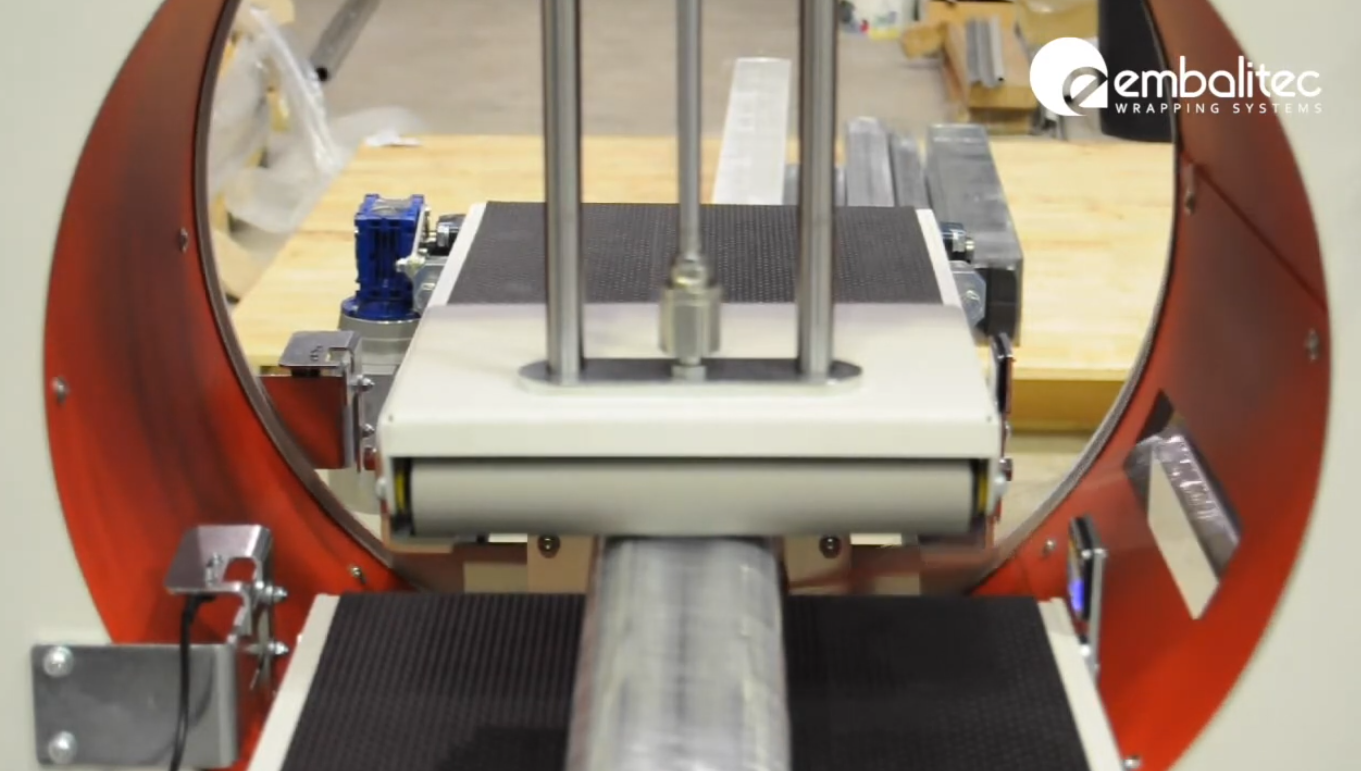

STEP 2

Film application

The crown rotates around the product as it applies stretch film. Its coordinated movement ensures the film is wrapped evenly and securely, covering the load with multiple layers based on the selected program.

Step 3

Cut and finish

After the wrapping cycle is finished, the crown stops applying the film and returns to its starting position. Simultaneously, the system readies the film for cutting for the next product, reducing downtime and maintaining a continuous, efficient wrapping process.

Lett Orbital wrapper features

Synchronous crown

Adjust rotation speed and feed with a variable speed drive and encoder for constant overlap and wrinkle-free wrapping.

Continuous/strapped modes

Continuous or sequential packing mode by strapping, according to the selected programme option.

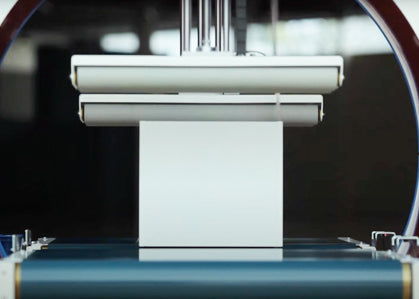

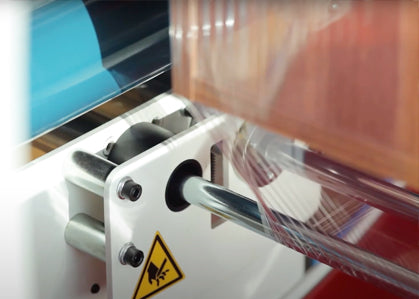

Pre-stretched film

Pre-stretch rollers stretch the film 200–300% and mechanically adjust tension to save material and ensure secure fastening.

Standard sized films rolls

The Lett Series uses standard 125mm and 250mm wide film rolls. These are the industry standard size rolls, meaning if you opt for these size rolls you wont be left wrap-less or "locked in" to one particulars suppliers film.

Customise your Lett

- Metal plate for short product (length 400mm)

- Motorised bridge for short product (length 300mm)

- Retractable motorised bridge for short (length 300mm) or narrow product

- Gripping system with wheels, special for doors

- Polyethylene side guide

- Side guide with free rollers and 5mm thick PVC cover

- Motorised "V" roller conveyor

- Motorised roller conveyor with self-centring side guide