ATLANTA STRETCH

SKU: XF-5113SA

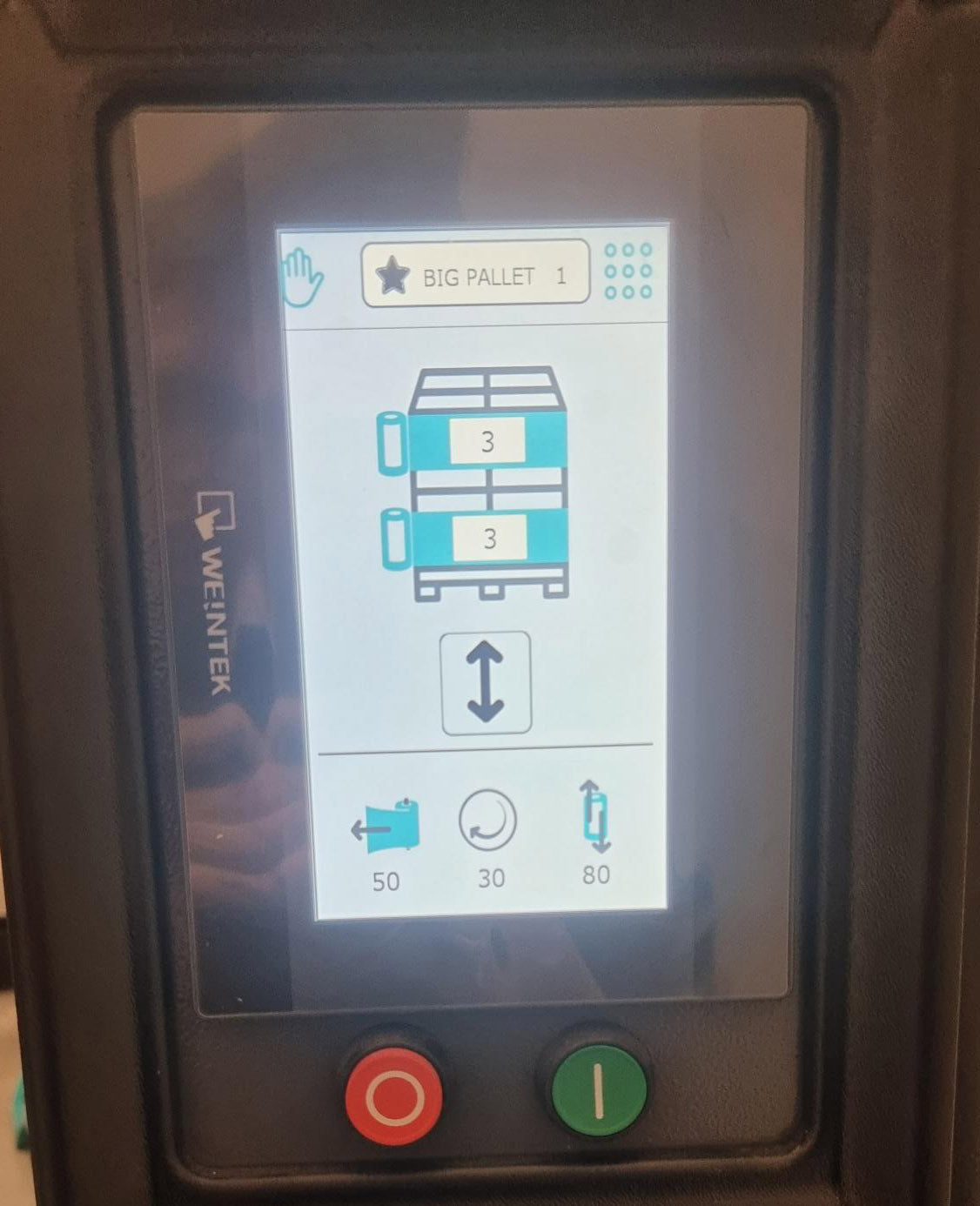

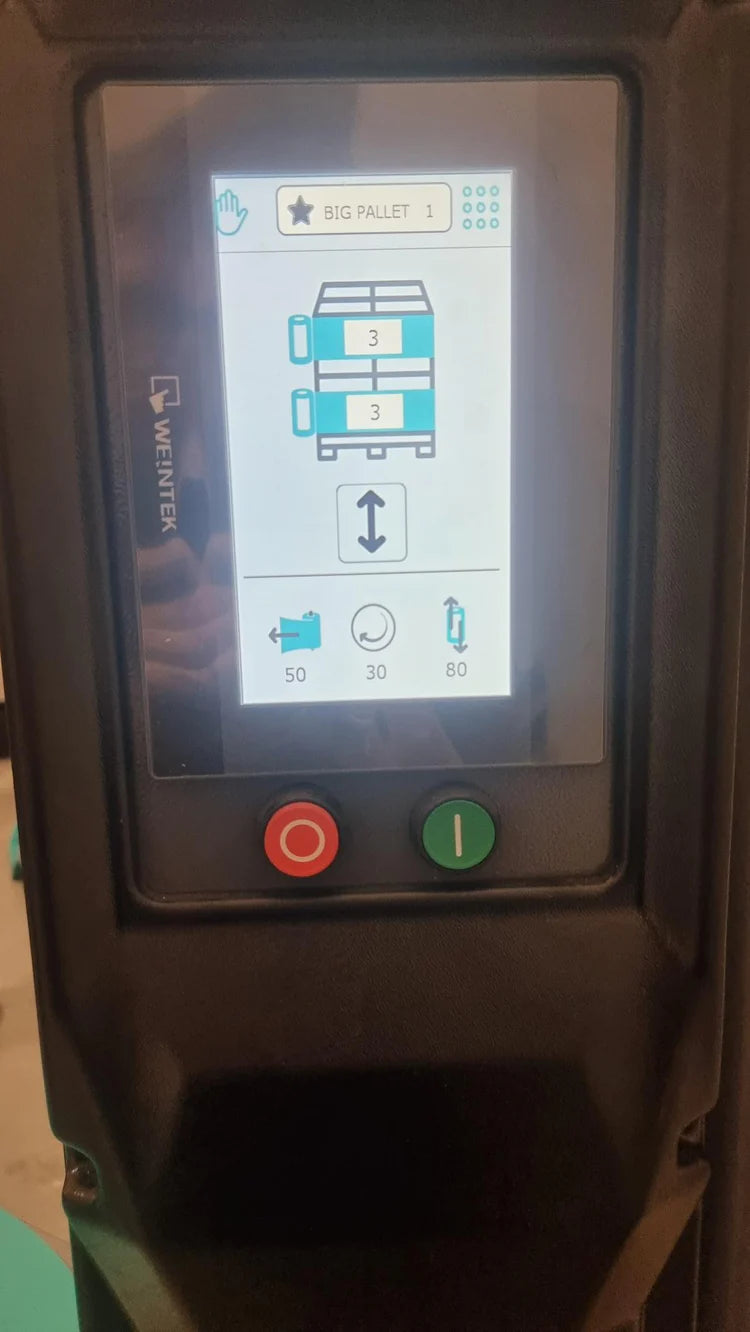

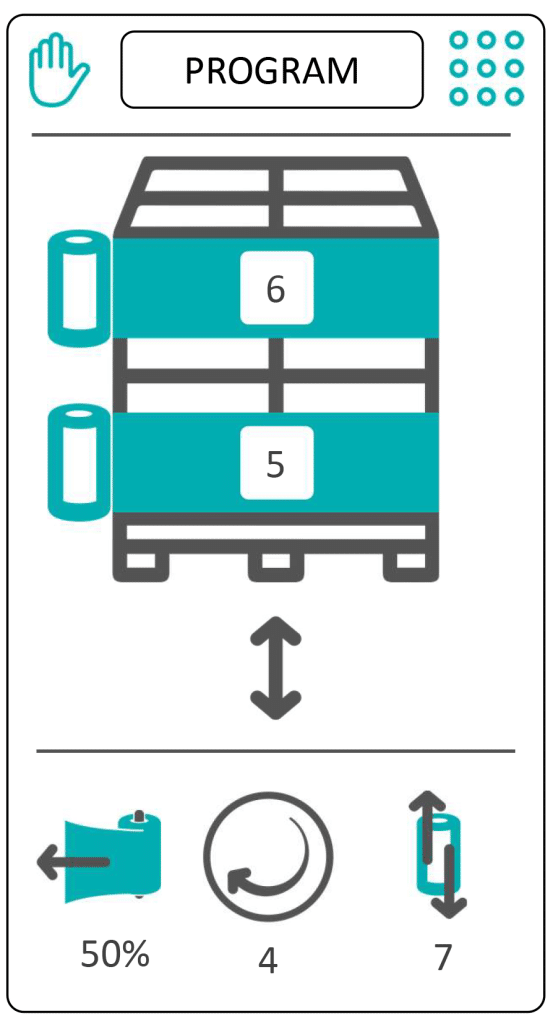

Mytho S Ayra- Automatic pallet wrapper with PreStretch – XF-5113SA

Mytho S Ayra- Automatic pallet wrapper with PreStretch – XF-5113SA

High quality AUTOMATIC pallet wrapper at an affordable price. No pneumatics and no automatic functions on the turntable make this automatic machine the most reliable and lowest maintenance on the market.

Enquiry Form

Technical

Total installed power

0,75 KW – 1,00 KW (with carriage PRS / PS)

Standard input voltage

230V mono-phase – 50/60 Hhz 10AMP

Outlet

and AU standard plug