Eva Semi auto pallet wrapper XF-2010

Eva Semi auto pallet wrapper XF-2010

Eva Pallet wrapper 1500kg, capacity, Easy to use panel. Made in Italy by ATLANTA STRETCH.

2 in stock

Enquiry Form

Atlanta Stretch Pallet wrappers

MPS Packaging sell pallet wrappers from international brand and Italian manufacturer ATLANTA STRETCH. ATLANTA STRETCH pallet wrappers are used throughout the world and known for their robustness, low maintenance and low cost of ownership.

MPS buy direct and sell direct, offering end users an unbeatable price for a high quality Italian made pallet wrappers.

Use of industrial Components

Industrial design & Components

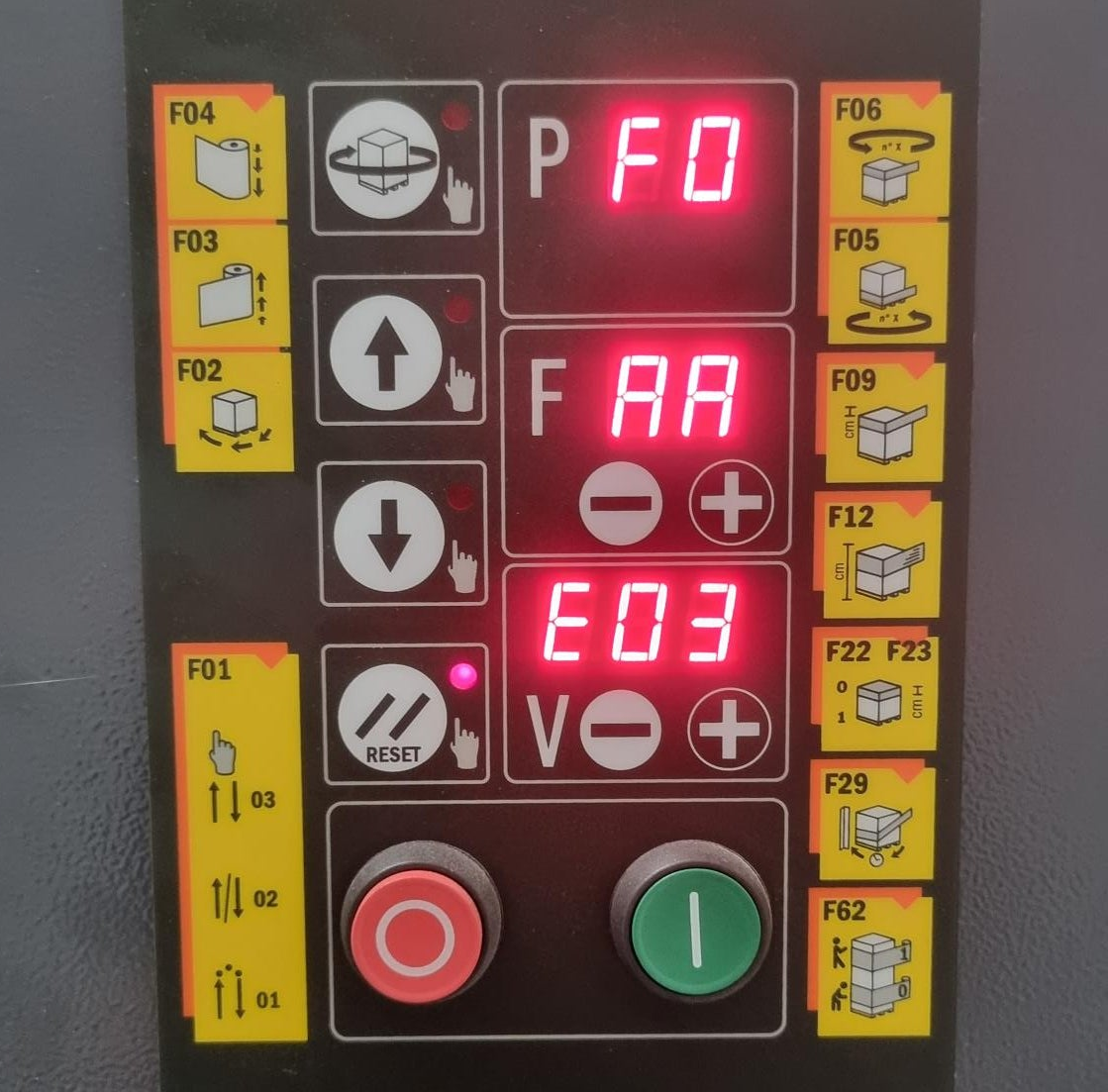

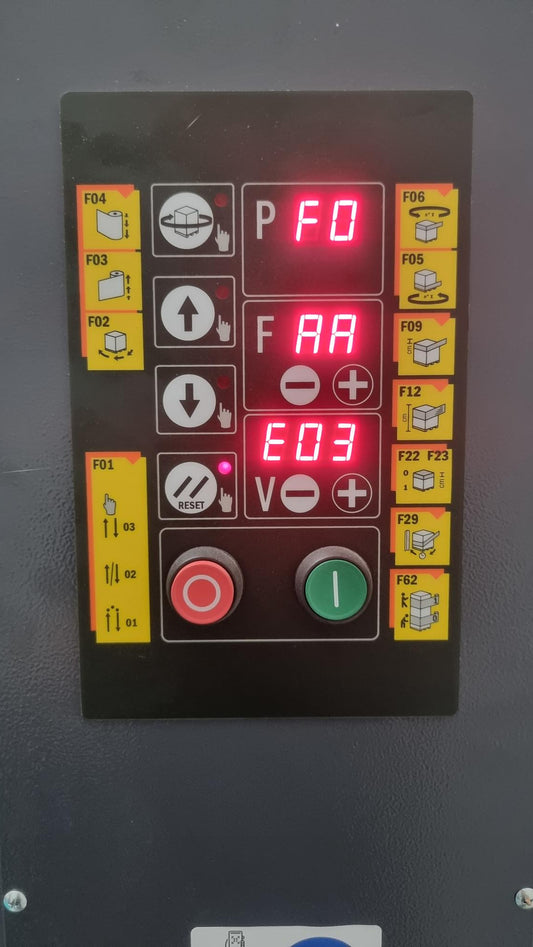

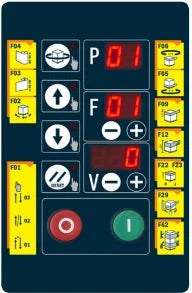

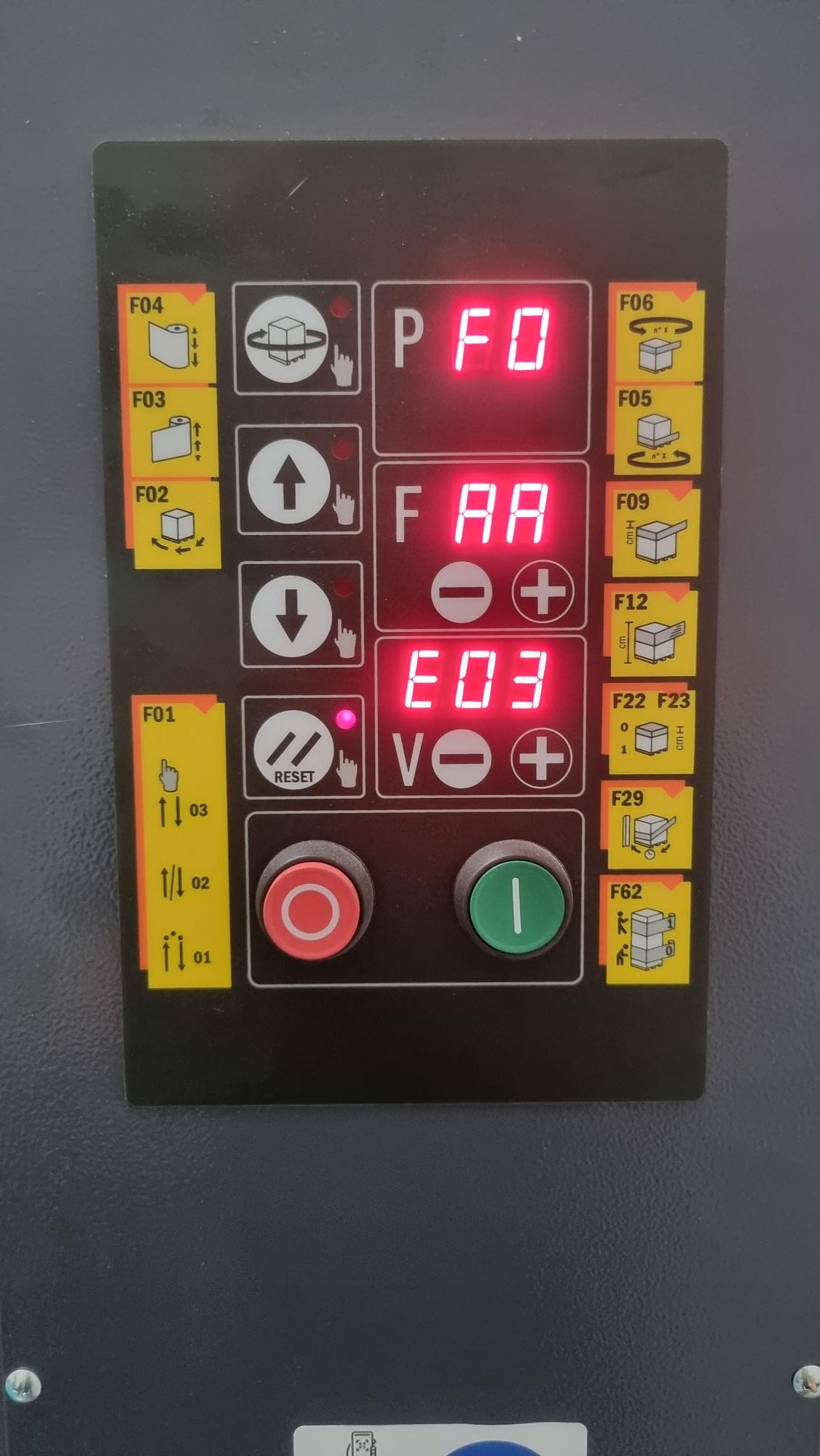

Atlanta stretch build machines with ease of replacement parts in mind. Where possible they use commercially available industrial components. Current machines use Siemens inverters and the power supply and buttons are all generic.

Generic components for high ware buttons

Industrial buttons

The Eva makes use of industrial buttons for the high use start, stop, enabling, main isolator and emergency stop. these buttons are quick and easy to replace if they ware out or break and easily obtainable from your local electronics supplier.

Atlanta stretch don't try to lock you into using their parts and buttons. Their goal is to build a robust machine with low service requirements in mind.

safe for all

Fully enclosed mast design

Atlanta stretch build machines with a fully enclosed mast design, this means that all components for the carriage to operate are inside the mast, the upper and lower limit switches, the chain, cable loom, microswitches and the main bearings of the flange are all internal.

This internal design design means there is less chance of components failing due to dust or moisture, they cant be knocked and people cant get their fingers in there.

Designed for Australia

1650mm turntable for AU Pallets

MPS import machines with 1650mm turntables, which means if you want to add a ramp to support AU pallets you can easily. a 1650mm turntable can fit an AU CHEP or LOSCAM on it with no overhang.

Modular Options

Upgrade now or later

ATLANTA STRETCH machines are Modular, which means upgrades like, ramps, scales, roping, auto cut or even the entire carriage is easily swap-able out.

Visit our pallet wrapper showroom

Dedicated pallet wrapper showroom

If you want to compare models up close, that's no problems, we have a dedicated showroom where we have a range of models setup for comparison,