Mytho S – Pallet wrapping machine – Prestretch – XF-5113S

Mytho S – Pallet wrapping machine – Prestretch – XF-5113S

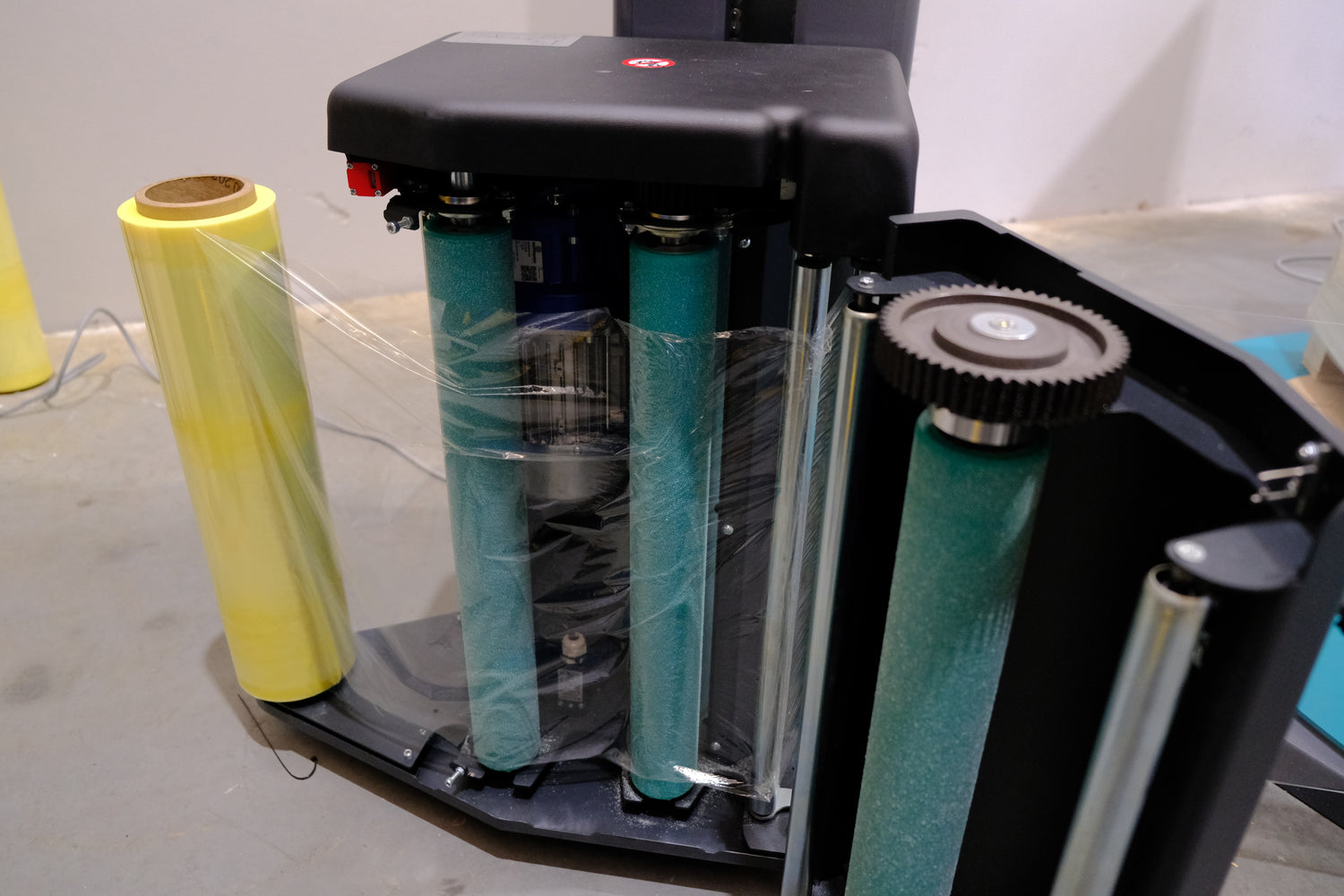

Mytho S pallet wrapper, Powered prestretch with HMI Panel and light tower, uses Siemens inverters and high quality parts.

In stock

Enquiry Form

Atlanta Stretch Pallet wrappers

We sell pallet wrappers from international brand and Italian manufacturer ATLANTA STRETCH. ATLANTA STRETCH pallet wrappers are used throughout the world and known for their robustness, low maintenance and low cost of ownership.

MPS buy direct and sell direct, offering end users an unbeatable price for a high quality Italian made pallet wrappers.

Use of industrial Components

Industrial design & Components

Atlanta stretch build machines with ease of replacement parts in mind. where possible they use commercially available industrial components. Current machines use Siemens inverters and the power supply and buttons are all generic.

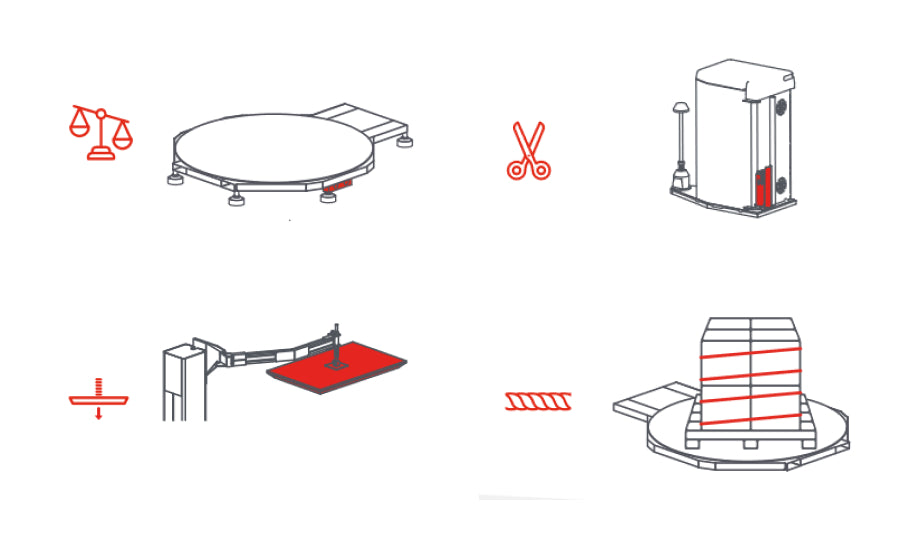

1650mm turntable for AU Pallets

Add short ramps easily

MPS import machines with 1650mm turntables, that means if you want to add a ramp to support AU pallets you can easily. a 1650mm turntable can fit an AU CHEP or LOSCAM on it with no overhang.

MPS machines from Atlanta that are 75mm high only need a 1.3m Long ramp. The use of a a 1.3m ramp on a 1500- 2000kg capacity machine needs far less servicing than any 25mm or or lower low profile turntable as there are considerably less bearings involved.

safe for all

Fully enclosed mast design

Atlanta stretch build machines with a fully enclosed mast design, this means that all components for the carriage to operate are inside the mast, the upper and lower limit switches, the chain, cable loom, microswitches and the main bearings of the flange are all internal.

This internal design design means there is less chance of components failing due to dust or moisture, they cant be knocked and people cant get their fingers in there.

component comparison

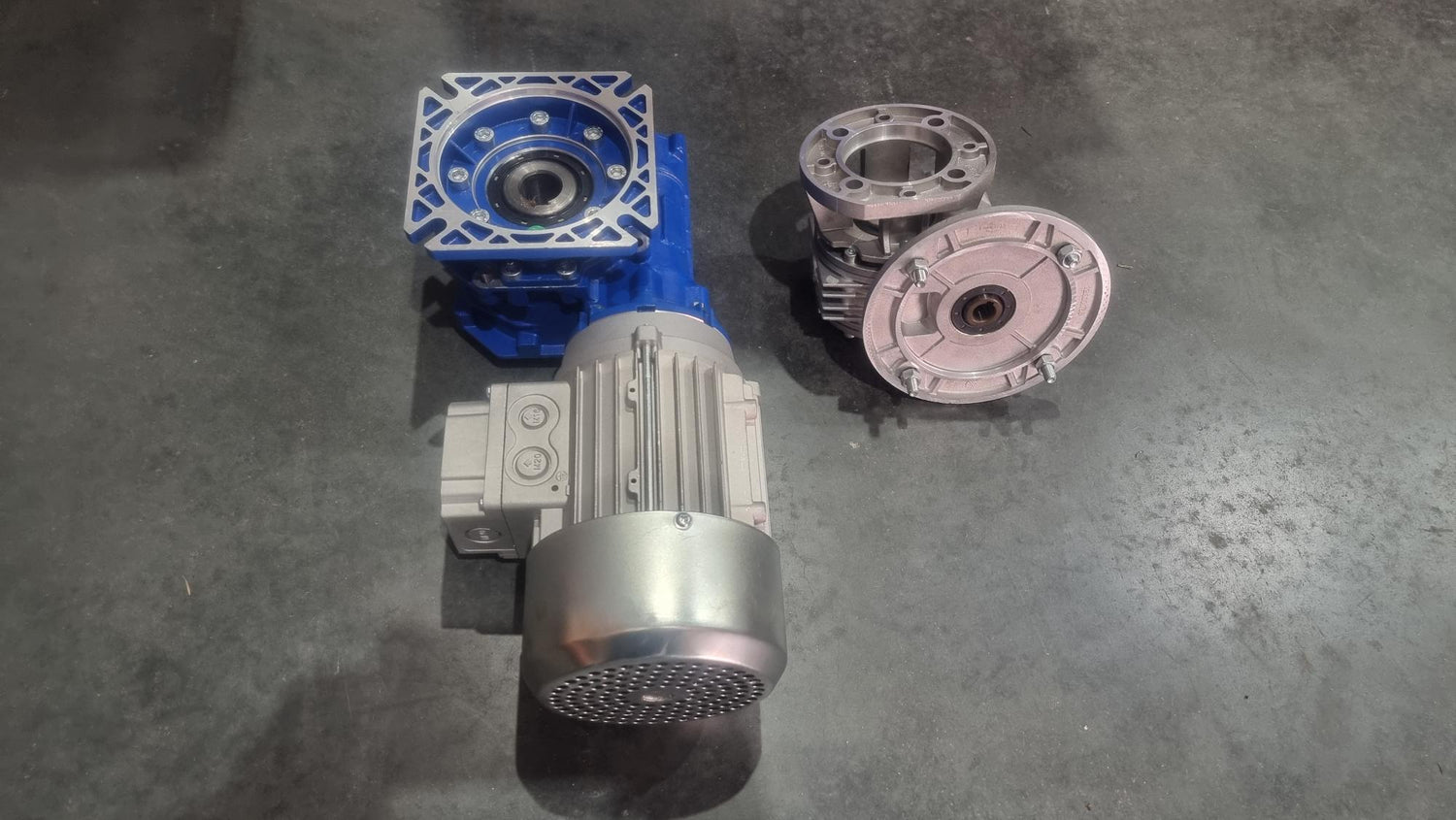

Heavy duty gearbox

The gearbox and motor to the left is from an Atlanta stretch synthesi or Mytho, the flange is mounted to the sealed gearbox using 8 large MX6 bolts. it is then bolted to the base of the machine using M10 bolts.

To the right is a gearbox used in other Italian made machines which for $ome rea$on retail for more than the Atlanta Synthesi. Despite their gearbox been mounted with 4x bolts of lesser gauge to a CAST steel flange.

If you're shopping around for machines we urge you to look at the build quality and components used for machines, weather you buy an Atlanta or not, we want to educate buyers and not have them stuck with an Alfa Romeo of pallet wrappers which might look cool as a weekend ride, but it only works half the time. Whats your daily pallet wrapper going to be?

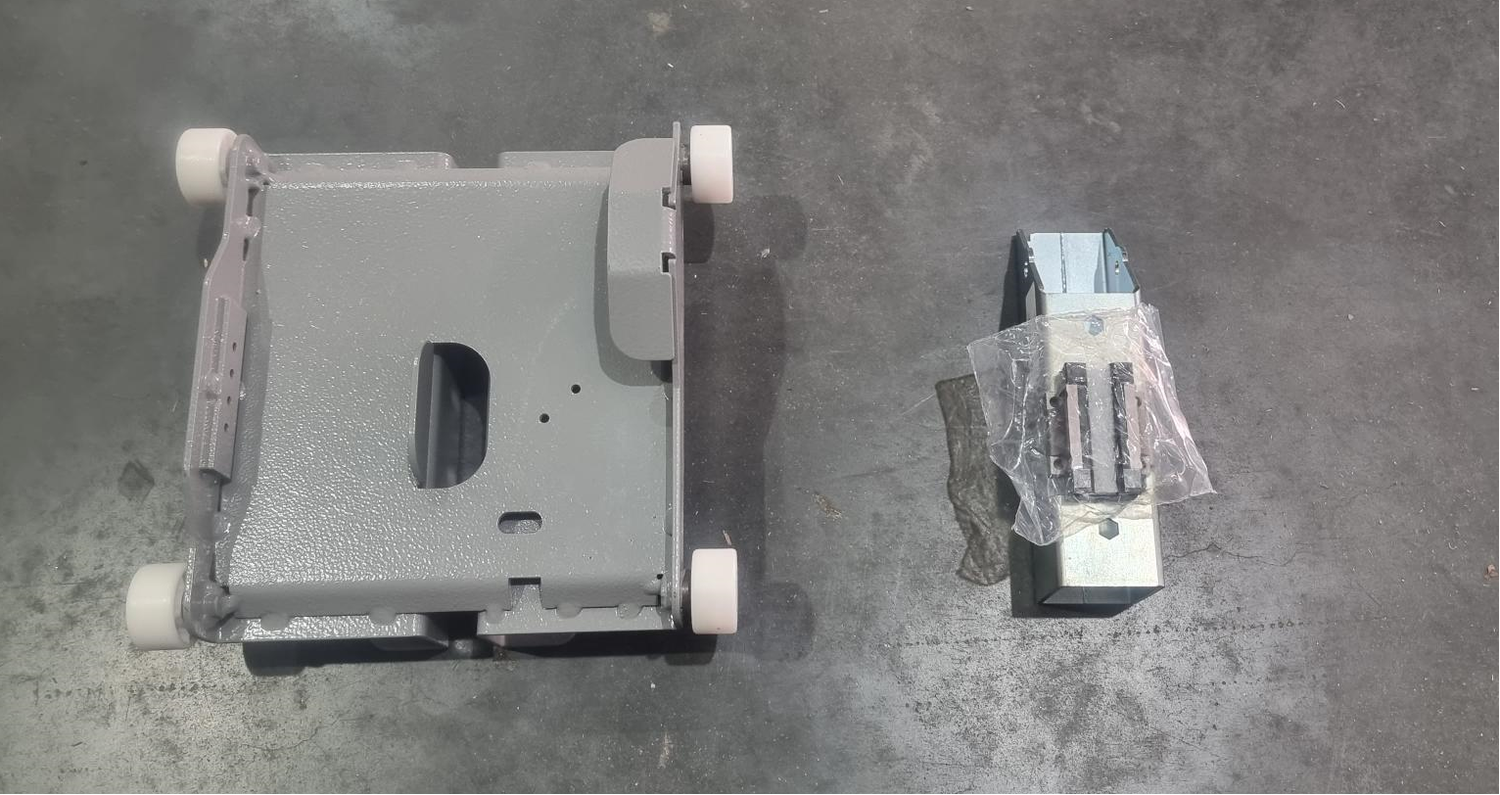

Component comparison

Heavy duty steel flange

The Left it an ATLANTA steel carriage flange and bearing setup for the mast, its responsible for bearing the weight of the stretchwrap, roll carriage, and force of the strechwrap been stretched also maybe a forklift bump or too.

This carriage flange is used throughout the range from our entry level machine the Eva through to the high end Mytho.

The right is a linier bearing and flange used in some other entry level and midrange models. Ask yourself, how much stretchwrap stretching force can a linier bearing take before you rip it off the rail?

Don't take our word for it, inspect any machine before you buy. but look for these points.

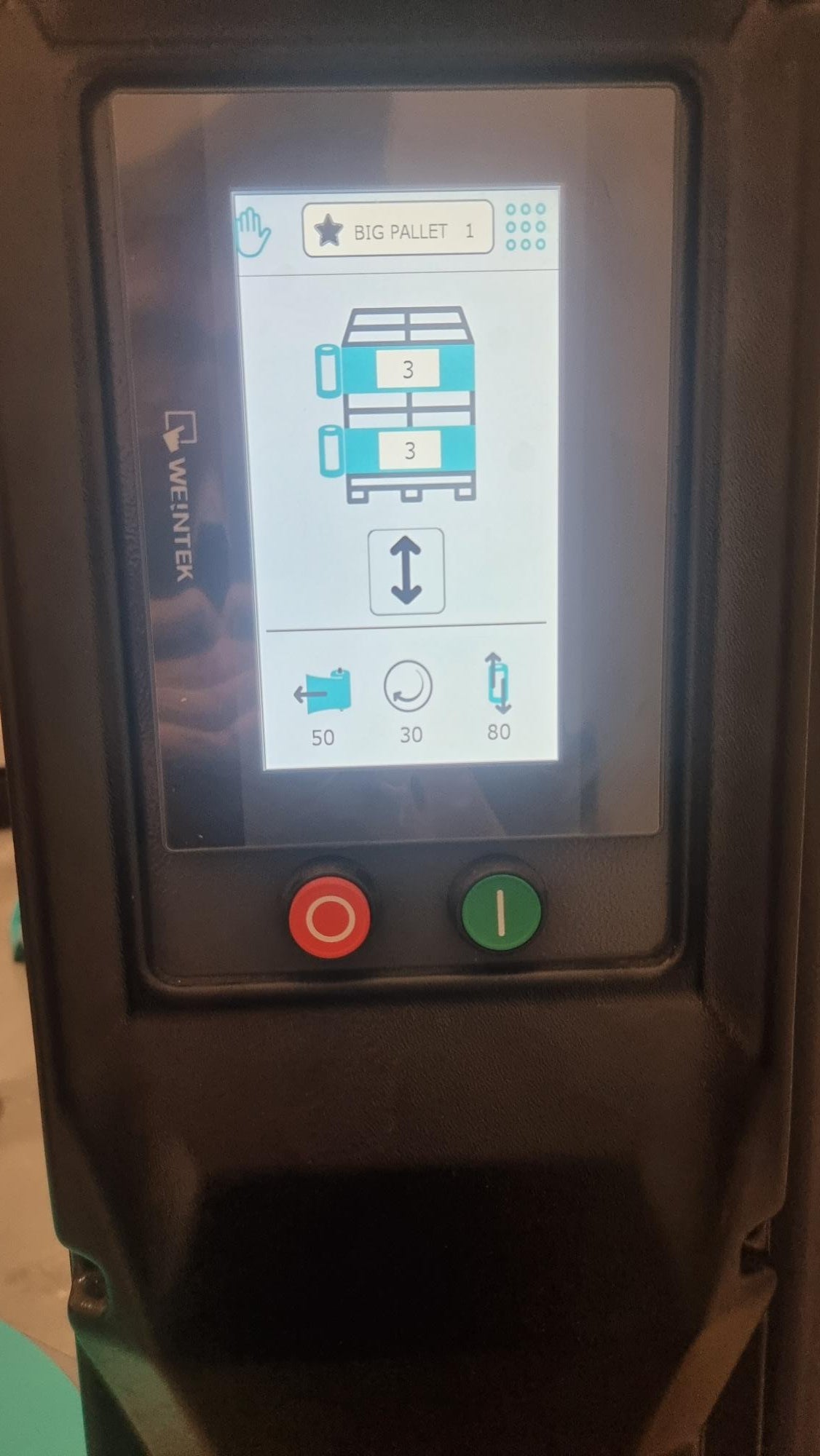

Generic components for high ware buttons

Industrial buttons

The Eva and Mytho S models and (Synthesi by request) make use of industrial buttons for the high use start, stop, enabling, main isolator and emergency stop. these buttons are quick and easy to replace if they ware out or break and easily obtainable from your local electronics supplier.

Atlanta stretch dont try to lock you into using their parts and buttons. Their goal is to build a robust machine with low service requirments in mind.

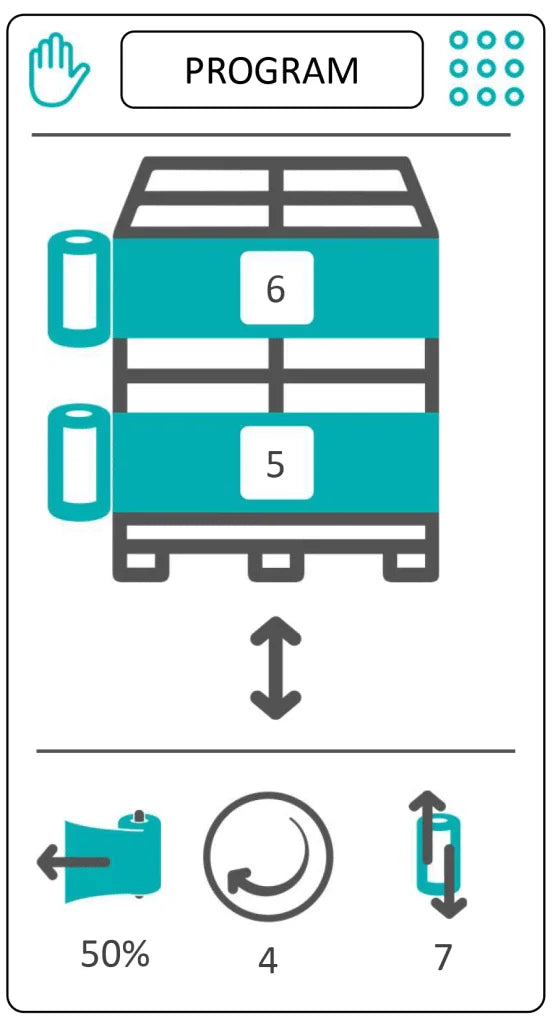

The east to use HMI panel on this image is from the Mytho S model.

Viste our pallet wrapper showroom

Dedicated pallet wrapper showroom

If you want to compare models up close, that’s no problems, we have a dedicated showroom where we have a range of models setup for comparison,