XC-4300 Air pillow machine

XC-4300 Air pillow machine

The XC-4300 air pillow machine suits our 4000 series air pillows, in Standard LDPE, paper and biodegradable. The XC-4300 features a basic and simple to use interface.

In stock

Air pillow machines through MPS

MPS Packaging has been packaging goods since 1977. Void filling has been a core part of our business since the introduction of Packaging peanuts for loose fill and then later air pillows.

MPS have a dedicated technical and service team avalible should the need for air pillow maitance ever araise.

Void fill and protection

-

Step 1

Add the sides and base of the void fill, You may not need this much protection depending on your product and its primary packaging.

-

Step 2

Add your product in where its most protected.

-

Step 3

Fill the void to the top, this elimianted movment of your product in the packaging while the void fill also absorbs and shock in transport.

-

Step 4

Tape it up, with some custom branded tape. Enquire with us for your own tape!

Buy Air pillows

Buy Pillows for XC-4300

Buy "4000 Series" Film for compatible film for the XC-4300

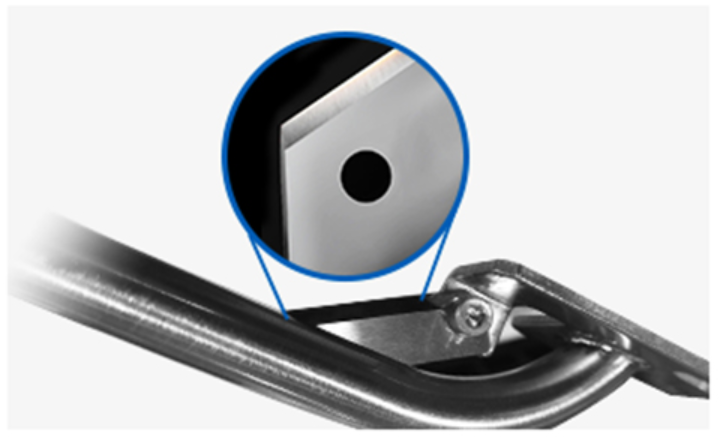

Tungsten steel blade

To reduce the need for replacement and downtime, the XC-4300 is fitting with a tungsten steel blade for cutting the air pillows.

After the pillows are filled with the air the blade cuts the side of the pillow opening where the air is inflated so to pillows glide around the air inflation nozzle.

Heating belt and block

The XC-4300 features a heating block for high precision temperature control and extended life spam, the precision heating block is needed to handle the more delicate pillows like biodegradable and paper.

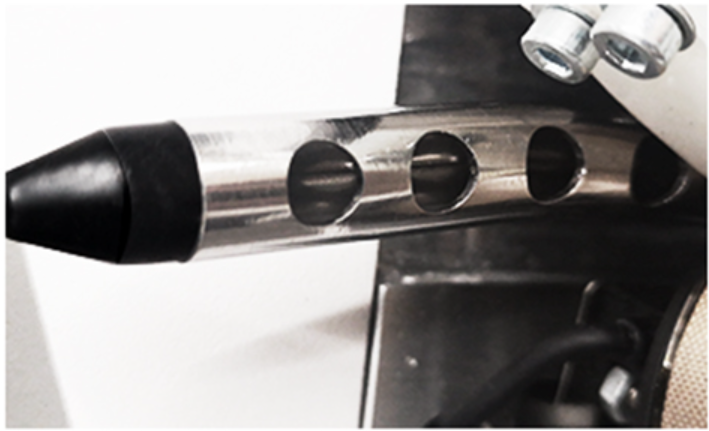

Metal blower tube

The metal blowing tube on the XC-4300 is of strong construction and allows for large air holes for quick inflation of pillows. the tube is easy to uninstall when replacing blades.